Cold Rolled vs Hot Rolled Steel: Understanding the Key Differences

If you’re unsure how to choose between cold rolled vs hot rolled steel for your procurement and usage needs, this article will help you understand the key differences. The decision to select one type over the other largely depends on the requirements of your specific application, including factors like cost, strength, surface finish, and ease of fabrication.

First of all, let’s briefly explain the differences between these two products cold rolled vs hot rolled.

1. Different Colors(cold rolled vs hot rolled)

Cold rolled vs hot rolled steels have distinct colors:

- Cold Rolled Steel: Typically silver in color. Its shiny and smooth surface is the result of the cold-working process. As the material is rolled at room temperature, it retains a clean, bright finish, making it aesthetically pleasing for applications where appearance matters.

- Hot Rolled Steel: Varies in color, often brownish due to the oxidation layer formed during the hot rolling process. When steel is heated to high temperatures and rolled, it develops a rougher surface and the oxidation causes it to have a more varied color, ranging from reddish to brownish tones. This oxidation layer can be removed or treated further, but it gives hot-rolled steel its characteristic appearance.

2. Different Feel(Cold Rolled vs Hot Rolled Steel)

The texture and edge quality of the two types of steel are also different:

- Cold Rolled Steel: Feels fine and smooth, with neat edges and corners. It is characterized by a polished and uniform surface finish. The rolling process at room temperature creates a tighter grain structure, contributing to its smooth texture and sharp edges. It’s ideal for applications that require precision and an aesthetic finish.

- Hot Rolled Steel: Feels rough and has uneven edges and corners. Due to the high temperature and stress of the hot rolling process, the surface texture is often less refined. Hot rolled steel may also have sharper or rougher edges, making it more suitable for structural purposes rather than aesthetic ones.

3. Different Characteristics(Cold Rolled vs Hot Rolled Steel)

The manufacturing process and properties of cold rolled vs hot rolled steel vary significantly:

- Cold Rolled Steel: Has higher strength and hardness due to the cold working process. The production process is more complex, making it more expensive. During cold rolling, the steel is processed at room temperature, which results in increased strength, hardness, and improved surface finish. Cold-rolled steel can also be further treated for specific mechanical properties, such as improved tensile strength.

- Hot Rolled Steel: Lower hardness but better ductility. It’s easier to produce and is generally cheaper. Because it is formed at higher temperatures, the steel retains a greater amount of ductility, making it easier to shape and manipulate. The trade-off for this increased formability is that hot rolled steel tends to be less strong and harder than cold rolled steel.

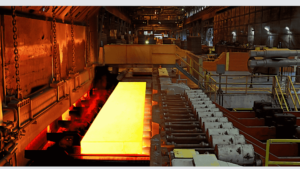

Advantages of Hot rolled steel sheets

Hot rolled steel sheets is a versatile material with several key advantages:

- Low Hardness and High Ductility: Easy to process and can be formed into various shapes. The process of Hot rolled steel sheets makes steel more malleable, allowing it to be easily shaped into large beams, sheets, or plates for construction and industrial uses. This makes hot rolled steel a go-to material in applications where flexibility and ease of fabrication are paramount.

- Thick and Strong: Moderate strength and good bearing capacity. Hot rolled steel can be manufactured in thicker forms, providing strength and support where necessary. It can handle heavy loads and stresses, making it ideal for structural applications such as beams, columns, and girders in construction.

- Good Toughness: Suitable for making springs and other components. After heat treatment, it can be used for many mechanical parts. Hot rolled steel’s excellent toughness makes it ideal for machinery parts and automotive components, which may undergo extensive wear and tear.

Applications of Hot Rolled Steel

Hot rolled steel is widely used in many industries, including:

- Shipbuilding

- Automotive manufacturing

- Bridges

- Construction

- Machinery

- Pressure vessels

The ability to form large shapes with high ductility makes hot rolled steel a preferred material for industrial and structural applications.

Applications of Cold Rolled Steel

Cold rolled steel sheets is commonly used in applications requiring high precision, strength, and a smooth surface finish.

- Packaging: Commonly packaged in iron sheets, lined with moisture-proof paper, and tied securely to avoid friction between the coils. This ensures that the steel arrives in good condition and is protected from environmental factors that could affect its quality.

- Specifications and Dimensions: Product standards specify recommended lengths and widths of cold-rolled coils, including allowable deviations. The manufacturing precision of cold rolled steel ensures that it meets the necessary specifications for specific applications.

- Appearance: The surface state varies due to different treatment methods during the coating process. Cold rolled steel sheets may undergo additional processes such as galvanizing, coating, or painting to enhance its resistance to corrosion or to improve its appearance.

- Galvanizing: The quantity of galvanizing indicates the thickness of the zinc layer on the cold rolled steel sheets, cold-rolled coil, measured in g/m². This helps provide additional protection against rust, increasing the steel’s durability in harsh environments.

Applications of Cold Rolled Steel

Cold rolled steel is extensively used in:

- Automobile manufacturing

- Electrical products

- Rolling stock

- Aviation

- Precision instruments

- Food cans

It is also gradually replacing hot-rolled steel in home appliance manufacturing due to its superior surface finish and strength.

Conclusion

Choosing between cold rolled vs hot rolled steel depends on your specific needs. Hot rolled steel is ideal for applications requiring ease of fabrication, cost-effectiveness, and structural strength. It’s particularly suitable for large-scale construction projects and industrial applications. On the other hand, cold rolled steel is best for applications that require precision, strength, and a superior surface finish. It’s preferred in industries such as automotive manufacturing, electronics, and precision engineering.

By understanding these differences, you can make informed decisions for your procurement and usage, ensuring that you select the right type of steel for your specific application. Consider the factors that matter most to you, such as strength, appearance, and cost, before making a choice between hot rolled and cold rolled steel.

(Some content on this website is reproduced from the Internet to provide more information. We respect the original work and the copyright belongs to the original author. If the source cannot be found, please understand and contact us for removal.)