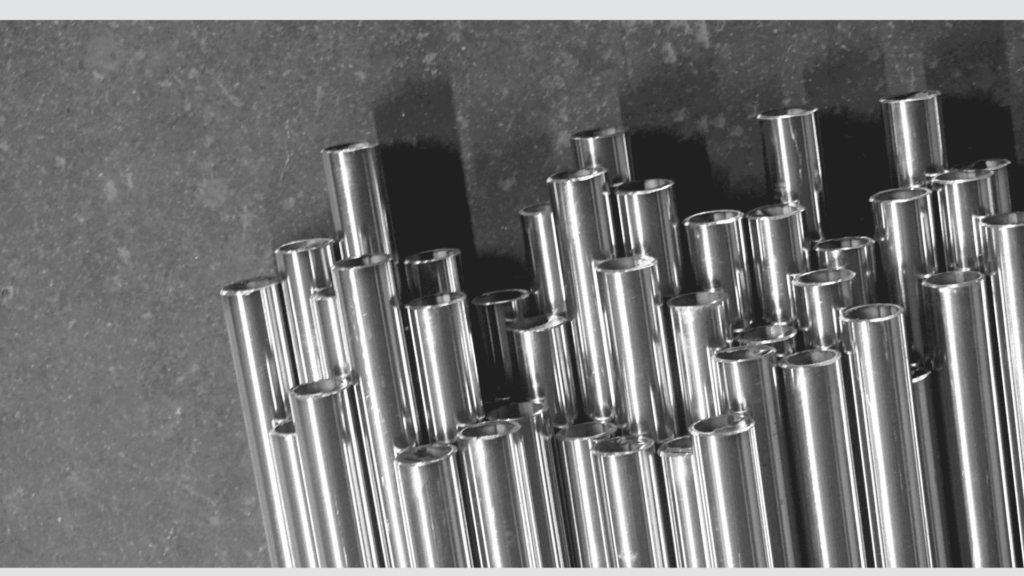

Energy transportation and energy infrastructure cannot be complete without steel pipes; steel pipes are fundamental to the energy business. Used in pipelines for crude oil and natural gas, steel pipes meet the strict requirements of a tough, strong and versatile material to support the growing energy systems including those in renewable energy.

Key Roles of Steel Pipes in Oil and Gas

Long-Distance Transportation:

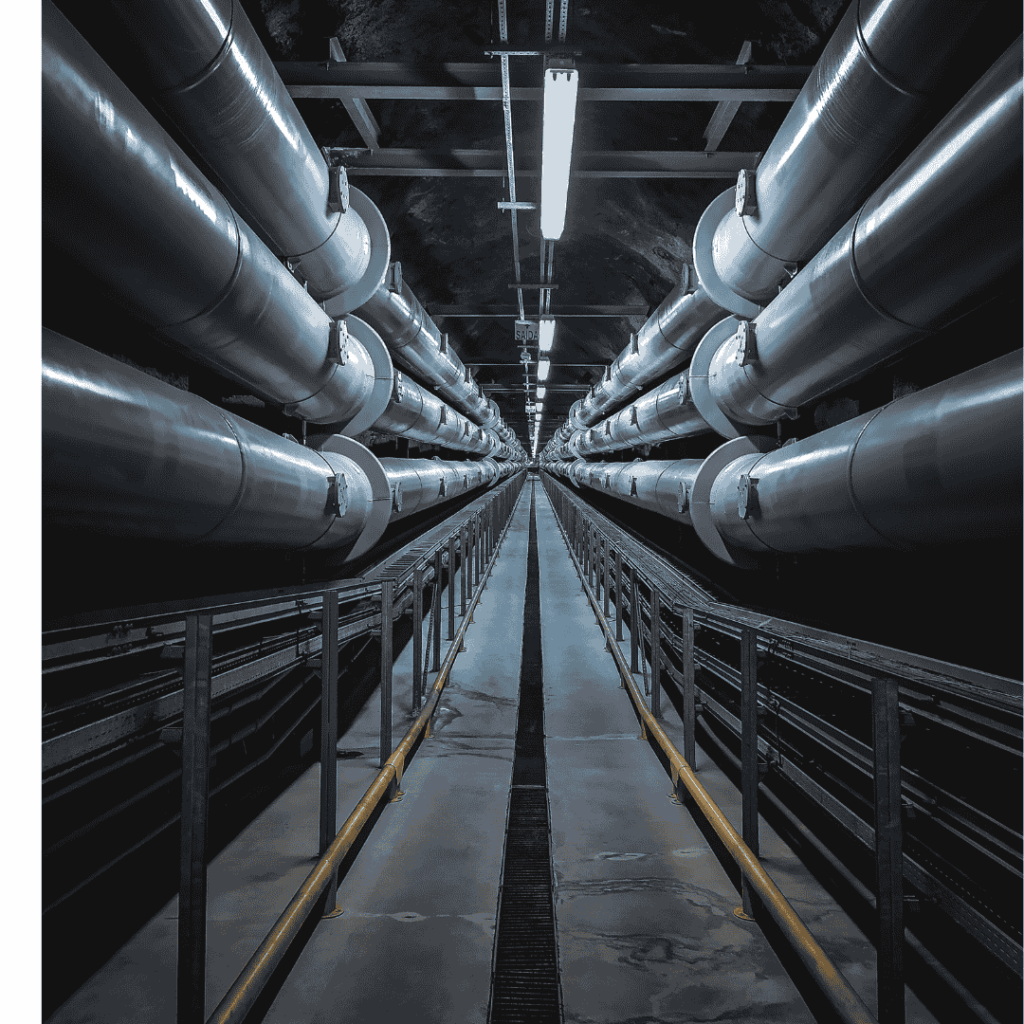

Extensive pipeline systems made out of steel pipes convey crude oil and natural gas from one point to another; from one country to another or even from one continent to another.

High-Pressure and Temperature Resistance:

.pipe networks are required to operate under conditions like high pressure and high or low temperatures. To overcome these challenges, steel pipes are suitable because of certain unique features.

Corrosion Resistance:

The current steel pipes are characterized by anti-corrosive coatings that shield the steel from corrosive impacts of the conveyed products and the surrounding environment.

Safety and Reliability:

It reduces the probability of losage and failure occurrences making steel pipes safe for energy transportation.

Real-World Applications of steel pipes

Onshore Pipelines:

Fixation steel pipelines are employed to transport extracted products to refinery and distribution centers.

Offshore Pipelines:

These steel pipelines are used for the transit of oil and gas from underwater resources to plants for treatment.

Distribution Networks:

The distribution networks of gaseous materials are constructed through steel pipes that convey gaseous products to residential areas and businesses.

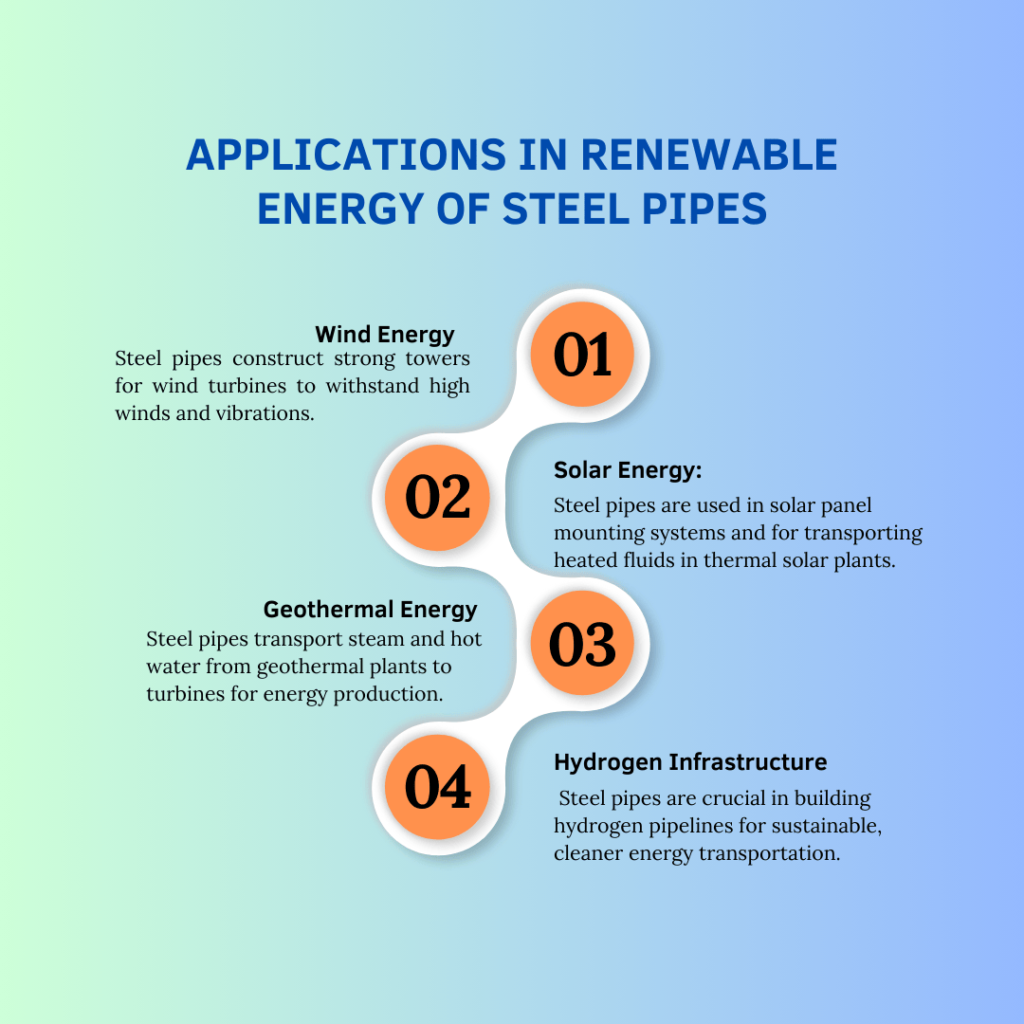

Applications in Renewable Energy of steel pipes

Wind Energy:

Steel pipes are utilized to give the required strength in the construction of the towers of wind turbines to sustain vane and vibrations.

Solar Energy:

In photovoltaic mounting structures and in thermal solar power plants the steel pipes are used to transfer the heated fluids.

Geothermal Energy:

In geothermal plants, pipes are made of steel that convey steam and hot water from the earth’s surface to the turbines.

Hydrogen Infrastructure:

One of the largest application segments of steel pipes is the construction of hydrogen pipelines to support a sustainable energy sector.

Benefits of Steel Pipes in Renewable Energy

Sustainability:

Since they are recyclers and have long service time, it would have been appropriate that steel pipes would support the principles of renewable energy.

Adaptability:

Incorporation of steel pipes can be well done in different types of renewable energy systems.

Cost-Effectiveness:

These pipes have a high level of durability, and therefore incurs little or no costs for maintenance and replacement.

Advantages of Steel Pipes in the Energy Sector

High Strength-to-Weight Ratio:

Suitable for severe utility in energy pipelines transport.

Versatility:

Suitable for onshore, offshore, and subsea topography of systems.

Environmental Compliance:

Steel’s recyclability ensures that sustainability in energy is well supported.

Challenges and Innovation of Steel Pipes

Steel pipes are used almost in every industry sector essentially used in the energy sector. They rely on their sturdiness as well as flexibility in various applications that have earned them a central role in many essential infrastructure. Nevertheless, no material is without problems that may cause it to either perform inadequately or simply have a shorter lifespan than expected. To address these challenges, innovation must be carried out in order to provide for modern energy needs with steel pipes that also conform to existing environmental requirements.

Important Challenges

Corrosion:

Steel pipes for instance also bear the problem of corrosion which is among the leading problems affecting the well being of any material. If the material is exposed to steam, acids, or freezing and boiling conditions it will ultimately deteriorate and become unreliable and have limited usage. This becomes a big problem in the regions where the environment is unforgiving, like the offshore platforms, geothermal plants and the likes since the corrosion process is quickened.

Environmental Impact:

The processing of steel has environmental issues, for example emissions of carbon and consumption of resources. Various industries are currently pushing on the manufacturers of steel pipes to reduce the ecological effects by making these steel pipes more sustainable.

Evolving Energy Needs:

The new development is competition in utilizing renewable energy and the increasing need for energy conservation. New practices including hydrogen pipeline transport and geothermal power plants have to be catered for by steel pipes and most of these come with other set peculiar conditions.

Innovations in Steel Pipes

Advanced Coatings:

The pipe products of today, for example, are capable of boasting of sophisticated anti-corrosive layers thus increasing their life span tremendously. These coatings also serve as a shield in that they deter moisture and chemical from getting to the steel surface. High risk application include offshore oil production facilities, bury pipelines and others that have benefited tremendously from epoxy based and other ceramic coatings.

Lightweight Alloys:

The modern advancement of lightweight steel alloys has been a revolution of the industry. These alloys keep virtually all the necessary characteristics of classical steel – strength and carrying capacity – but efficiently lessens the contractor’s worries of weight – transport, erection, and overall system requirements.

Smart Technologies:

This means that through the use of smart technologies that has modernized the handling of steel pipes. Smart pipes have various cores that are built to monitor parameters like pressure, temperature as well as corrosion rate on the pipes. Besides improving safety, this innovation also helps in saving the maintenance expenses as the system promptly predicts the requirement for intervention in due course.

The Road Ahead:

As we can see steel pipes still change with the development of modern energy systems. Issues like corrosion, environment, and new energy demands are already on the move to be solved. Ceramics increase sturdiness and leightness, smart systems enable increased accuracy and possession of the highest standards.

As the size of renewable energy systems increases and more industries look for a more efficient way to transport energy, steel pipes will play a role of connecting energy from the current more conventional infrastructures. The steel pipe industry, incorporating these innovations of the industry in the production process guarantees its relevance and necessity in the energy sector for many a year.

Conclusion

Therefore, depending on the use in energy, sector it is clear that steel pipes are USEFUL element in energy transport in the world. These have unique characteristics like high strength, durability and flexibility to suit the non-renewable oil and gas operations besides the renewable energy forms such as Wind, solar and geothermal power systems. Long-distance pipelines Offshore reserves and Hydrogen transportation system are some of the lifeline structures that use steel pipes. However, for current application of steel pipes, some challenges like corrosion, environmental issue and unpredictable energy requirements make the future development need to be innovated. Recent technological developments in surface protection, materials science and nanotechnology have contributed to enhanced anti-corrosion coatings, light weight high strength alloys and smart technologies to meet the modern energy steel pipes infrastructure requirements. These innovations have enhanced safety, eliminated or minimized on the costs of maintenance costs and increased the durability of steel pipes thereby enhancing sustainability of these pipes thus cutting expenses. As the world gradually transforms to the use of renewable energy in the energy infrastructure, the part played by steel pipes remains one that connects the old energy infrastructure with the new one. Sustainability a key policy draws shape from the desirable attributes of steel pipes that include recyclability and capability to work with new technologies and for long.